A multidisciplinary team of engineers and healthcare practitioners at the University of Johannesburg (UJ) has used open-source designs to develop a cheap, minimal viable ventilator with elements that can be produced through 3D printing and laser-cutting techniques.

The team says it has taken a three-pronged approach towards support for critical-care technology development in response to the Covid-19 crisis, which is expected to peak between July and October this year in South Africa.

Responding to initial reports that between 40% and 70% of South Africans could get infected with Covid-19, depending on the national response to the crisis, the Faculty of Engineering and the Built Environment is coordinating efforts to further develop open-source ventilators; support repair and maintenance efforts to bring out-of-warranty equipment into service; and to make rapid prototyping facilities available to enable personal protective equipment manufacturing.

The latest reports indicate that South Africa has less than half the number of ventilators needed to deal with peak infections.

News reports state that the public healthcare system has 1 111 operational ventilators, with 2 105 operational in the private healthcare system.

The UJ team believes this will not suffice, owing to the expected number of infections.

The team, led by UJ’s Dr Deon Sabatta and Dr Samson Masebinu, identified several “simple, safe and scalable open-source designs” that could potentially meet the strict specifications for use with patients.

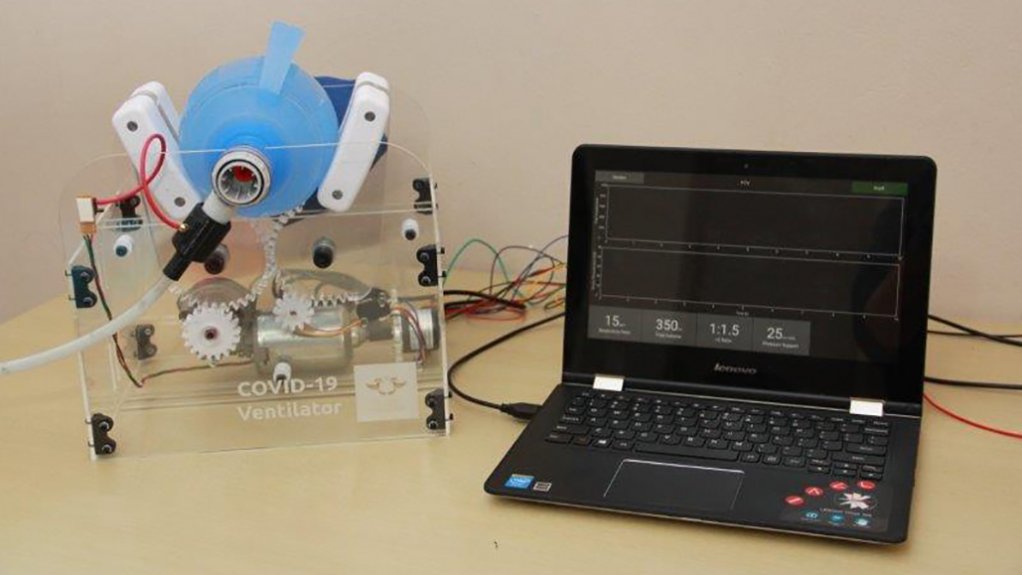

By building on these open-source designs, the team says it has managed to develop a minimal viable product with elements that can be manufactured through 3D printing and laser-cutting techniques.

These designs will support the development of critical control systems that protect a patient supported by a ventilator.

“Ventilators are complex medical devices, and it is more intricate than simply squeezing a bag,” says Sabatta.

“Our product includes devices such as pressure sensors, flow sensors and a number of control algorithms.

“It can, therefore, be set up to perform more advanced ventilation tasks such as pressure support ventilation or synchronous intermitent mandatory ventilation.

“This is a step up in ventilation support, by being able to assist patients further when they are tiring from being on continuous positive airway pressure systems for extended periods of time.”

DECOMMISSIONED

The UJ Process Energy and Environmental Technology Station (UJ-PEETS) is supporting efforts to identify decommissioned ventilators at public and private hospitals and to bring this out-of-service equipment back online.

“Through our repair and maintenance undertaking, this assignment will build on the principles of circularity and create employment opportunities since there are large amounts of equipment that can be repaired and calibrated for reuse, especially beyond our borders in South Africa,” notes Masebinu.

“There is no sector more critical at this moment than healthcare, which is why we are proud to play a role in helping to produce and revamp these critical life-saving devices.”

The UJ-PEETS team says it is gearing up to support and upskill small and medium-sized enterprises in the clinical technical services sector to deliver on the 500% to 1 000% growth in ventilator production needed globally to prevent Covid-19 deaths owing to product shortages.

EMAIL THIS ARTICLE SAVE THIS ARTICLE ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here