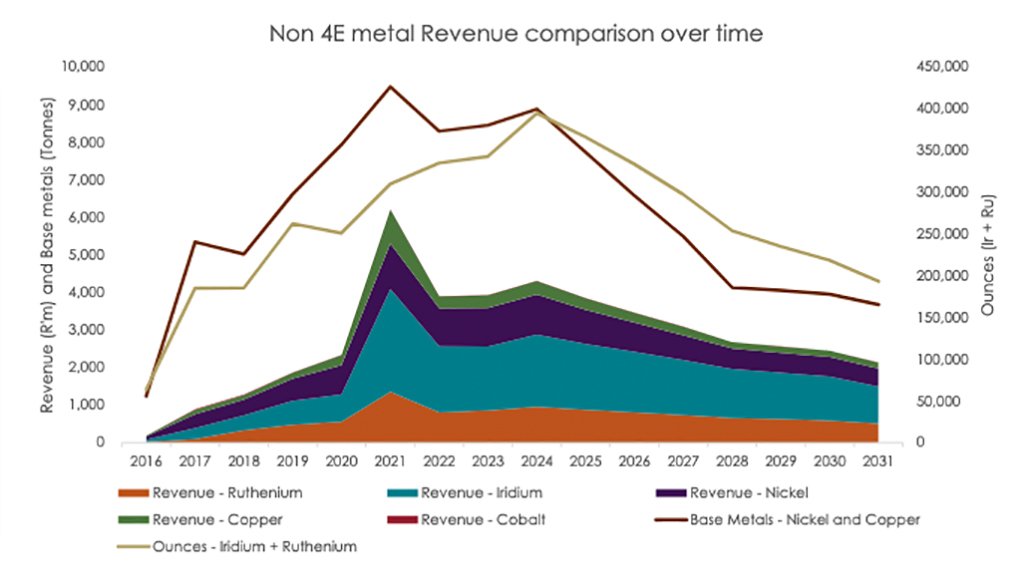

JOHANNESBURG (miningweekly.com) – Precious metals mining company Sibanye-Stillwater on Friday highlighted the quality elevation of its price-discounted nickel sulphate crystals to price-premium battery grade through the introduction of the Thakadu Battery Materials operation into the Base Metal Refinery in North West province.

The Thakadu process, Sibanye-Stillwater pointed out, also recovers cobalt, previously lost to the crude nickel sulphate crystals.

Thakadu sources crude nickel sulphate crystals from Sibanye-Stillwater and shares in proceeds in a profit-share arrangement. In a nutshell, Thakadu adds value to what was being disposed of at considerably lower value.

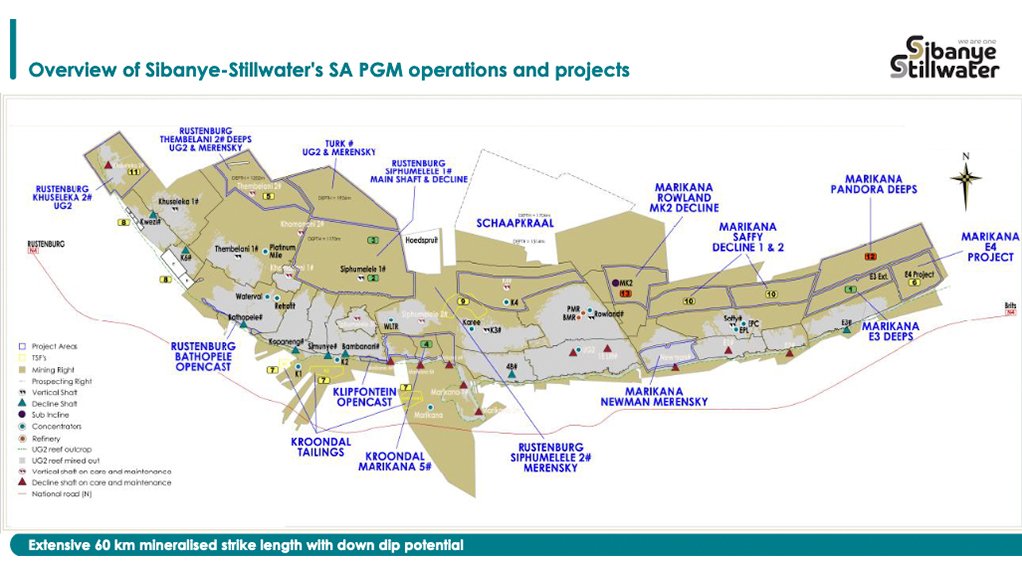

Presenting on its South African platinum group metal (PGM) operations during a Bank of America conference virtual site visit, the Johannesburg- and New York-listed Sibanye-Stillwater displayed a slide on Thakadu under the heading of “other metals contributing to the bottom line”.

Mining Weekly can report that Thakadu, operating as an independent startup, succeeded in turning a PGMs-linked nickel solution into sought-after battery material that is helping to make the world a greener place.

Crude nickel sulphate crystals were previously sold at a discount on the London Metal Exchange (LME). That has been reversed with the Thakadu-processed higher-priced battery grade nickel sulphate now adding to revenue generation.

Sibanye-Stillwater described the battery grade nickel sulphate as forming part of its green metals strategy.

Mining Weekly reported in April 2021 that the Thakadu team of local battery material achievers were planning first-mover advances into new geographies.

At that stage, Thakadu, headed by CEO Ruli Diseko, had a pipeline of new projects in place that would involve the use of locally developed intellectual property, proven process technology and first-mover advantage to fast-track other assets under development in Southern Africa and North America.

In what is a story of world-class local innovation, Thakadu created its own proprietary process at Mintek, working with a team of scientists.

Thakadu identified an opportunity at the bottom of the cycle, borrowed money and succeeded in building its plant while facing considerable headwinds.

When Thakadu began investing that borrowed money in its plant in Marikana from 2016, its counterparty, the then Lonmin Platinum, was in the midst of major financial strain.

Thakadu at the stage of the Mining Weekly report, had an installed capacity of 30 000 t/y of nickel sulphate and was targeting an average steady state of about 25 000 t/y.

The nickel sulphate solution piped for processing from the BMR was formerly crystalised and sold as lower intermediate.

As a producer of high-quality, high-purity battery-grade nickel, Thakadu receives a business-to-business price, with customers in China, Japan, Korea, Europe and Latin America giving a price premium over the LME’s nickel price.

Thakadu has extracted advantaged economics out of processing at source, within a long-standing PGMs processing environment.

When the cathode-focused product gets to export destinations, development into precursor materials requires even more advanced chemistry. Depending on the chemistry, it could become, for example, nickel-cobalt-aluminium oxide, or nickel-cobalt-manganese, at the different combinations used in different batteries.

EMAIL THIS ARTICLE SAVE THIS ARTICLE ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here