JOHANNESBURG (miningweekly.com) – Collaborative marketing of platinum group metals (PGMs) has the potential to add a million more South African jobs and contribute R8-trillion more to the economy as the world greens and lowers carbon intensity.

The combination of green hydrogen displacing natural gas and fuel cell electric vehicles (FCEVs) displacing internal combustion engine vehicles, could result in net carbon dioxide savings of up to 11% of the Paris Agreement’s 2030 targets. (Also watch attached Creamer Media video.)

A PGMs growth opportunity for South Africa of between 34% and 51% by 2030 from the current annual base of 4.7-million ounces can be provided by FCEVs and hydrogen electrolysers.

Investments in hydrogen of $300-billion to $1-trillion are expected in the next decade or so as demand increases sevenfold up to 2050, with most of that focused on generating green hydrogen at cost-effective rates from electrolysis.

“There are over 30 countries in the world that already have programmes in place around moving the hydrogen economy and quite a few countries have really put their money where their mouths are," outgoing Minerals Council South Africa CEO Roger Baxter told Tuesday’s PGMs Industry Day, covered by Mining Weekly. Baxter is also chairperson of the World Platinum Investment Council.

Australia, wich has invested $4-billion in growing the hydrogen economy, is working with companies to lower green hydrogen to $1.50/kg, the competitive point.

“The journey is on and when you get this critical mass of people focused on the issues with the brightest and best brains in the world, including from a South African perspective, you will see how this is going to change and shape the game in terms of green hydrogen going forward,” said Baxter, who emphasised South Africa’s pre-eminent position as the overwhelming source of global PGMs.

“Let’s not beat around the bush. Let’s just appreciate that 87% of the world’s known reserves are locally based. If you include Zimbabwe, it takes it up to over 90%,” he said.

The focus of the National Platinum Strategy for South Africa, developed by the Minerals Council, is to add R8-trillion to South Africa’s economy by 2050 and a million additional direct and indirect jobs.

PGMs are already playing a growing role in the global energy transition to net zero.

“This is a sector that has incredible potential, but it needs incredible collaboration to take place between government, the mining industry, organised labour and communities on how we tackle the short-term issues.

“We have made some progress on the electricity front in unlocking private sector investment in electricity, security and rail constraints. Ten per cent of the average basket price of the PGMs mining sector is chrome-related. Only 30% of our chrome is being transported by rail at the moment. The rest is going on road, as an example,” Baxter told the in-person and online event, chaired by mining stalwart Bernard Swanepoel.

“A concerted and coordinated effort between the public and private sector, supported by the framework of the National Platinum Strategy, is needed to fix the short-term issues and then to focus on the long-term issues to realise the promise that PGMs offer.

“I’ve lived my life according to this phrase that comes from President [Nelson] Mandela, Madiba, the father of our nation, who said, ‘a vision without action is just day-dreaming, action without a vision is merely passing time. But a Vision with action can change the world'.

“I really do believe that we can change the world if we work with government collaboratively to take Africa’s PGMs industry forward,” said Baxter.

In 2021, the 277 t of PGMs produced by 172 159 direct employees for R347-billion, represented nearly 40% of the total minerals sold by South Africa.

“This is an industry that really does matter for the economy, with R67-billion worth of wages paid. My estimate is that roughly 500 000 people have jobs within the PGMs sector, which is really important to the economy of our country,” added Baxter.

PGMS – THE GREEN METALS

PGMs in autocatalysts transform noxious vehicle exhaust gases – hydrocarbons, nitrogen oxide and carbon monoxide – into more benign components of water, carbon dioxide and nitrogen gas.

“Green hydrogen is starting to change the world and I think we’re on the slope of enlightenment when it comes to fuel cells,” said Baxter. Green hydrogen – generated by electrolysers using renewable energy – is key to decarbonising heavy industry and everyday activities.

Minerals Council launched the first building-based fuel cell installed in Africa to demonstrate that the technology really does work. The PGM-based proton exchange membrane (PEM) technology is well-suited to using intermittent renewable energy feed such as from solar.

South African mining has been able to unlock 9 GW of renewable energy projects through its engagement with government.

Hydrogen fuel cells, an environment-friendly alternative for delivering power, emits only medical grade carbon dioxide, of the kind used in cool drink bottling, and water, which can be returned to the circuit, as the Minerals Council did in the case of its own 100 kW fuel cell.

Platinum is used as a catalyst in both PEM electrolysers and PEM fuel cells, and iridium is also used with platinum in PEM electrolysers to produce hydrogen.

Ruthenium in PEM fuel cells with platinum is scalable from small devices to heavy duty transport.

An indication of the advance and thrifting that has taken place in the use of PGMs in car exhausts since the 1970s is that exhaust emissions from one car sold in the 1979s is the equivalent of the emissions from 100 cars sold in 2021.

The 99% reduction is testament to technology advances brought about by the working of the PGMs sector with the automotive sector in the last 50 years.

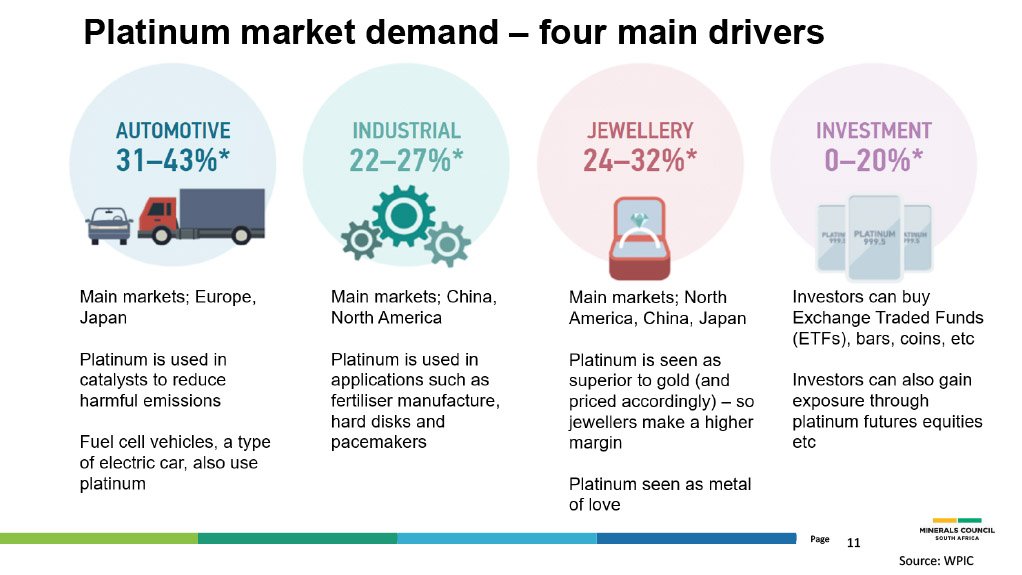

INDUSTRIAL DEMAND FOR PLATINUM

In addition to PGM vehicle emission catalysts, exhaust system catalysts, catalysed particulate filters and emission absorbers convert combustion engine nitrogen oxides and sulphur oxides pollutants, the metals also play a role in the chemical and petroleum, dental and biomedical, electrical and electronic glass, pollution control and several other sectors.

“Just think of how this has helped to change the world for the better,” said Baxter.

Palladium is the most used metal to make autocatalysts, followed by platinum and rhodium, and South Africa is the largest source of all three metals combined.

INVESTMENT DEMAND

The scarcity value of PGMs and platinum in particular is illustrated by the gold mined by South Africa filling three-and-a-half to four Olympic-sized swimming pools compared with all the platinum mined in the history of humankind being only ankle deep in one Olympic-sized swimming pool.

“On the investment demand size, it’s been a phenomenal exercise to have worked with the World Platinum Investment Council and engaging the global investment community. Platinum has been the critical focus at this stage and the investor interest has been phenomenal over the last couple of years realising a store of value,” said Baxter.

THE OUTLOOK

As the demand for internal combustion engines (ICE) eases toward the 2030s as many regions begin to slow down the use of ICE vehicles, FCEVs are expected to be the main driver of PGMs demand to as much as three-million ounces a year.

“But I think what’s more important and critical at a global level, is the role that FCEVs will play in heavy-haul mobility,” said Baxter, as he displayed the picture of a 40 t Daimler GenH2 hydrogen fuel cell truck that has a 25 t payload. Its targeted 1 000 km range is enabled by two platinum-intensive 150 kW PEM fuel cells.

“In our view this could be a significant component of global demand for hydrogen and platinum in the future. Heavy haul is expected to be one of the first segments to achieve economies of scale. That’s because it’s just so difficult to condense enough energy into lithium-ion battery cells that eventually two-thirds or three-quarters of the truck are basically batteries if you want to achieve the same impact.

“This could play a major role and when you have organisations buying 600 different trucks to roll out their deliveries of beers, for example in California, it’s quite exciting to see the potential. What is currently 1% of the global truck market is expected to be 50% of the global truck market by 2035, which is quite a significant jump that will take place over that period.

“Based on this growth, we reckon an additional two-million ounces of platinum could be taken into this market in due course. With a ten-year view, I think we will see demand for FCEVs being bigger than catalytic converter demand at the global level,” said Baxter.

“What we’re finding at the World Platinum Investment Council is that there is very much a shifting sentiment in the investor community about the potential and role of platinum in greening the world economy.

“There are significant savings that can happen from green hydrogen, independent energy security and with the rise of fossil fuel prices and the economies of scale over time, green hydrogen, if we can get the pricing down, will play a significant role. It’s becoming more attractive for private funding and there’s quite a lot of work that’s being done by different organisations looking at new innovative technologies around the hydrogen - platinum itself is a proxy for investing in the hydrogen economy,” said Baxter.

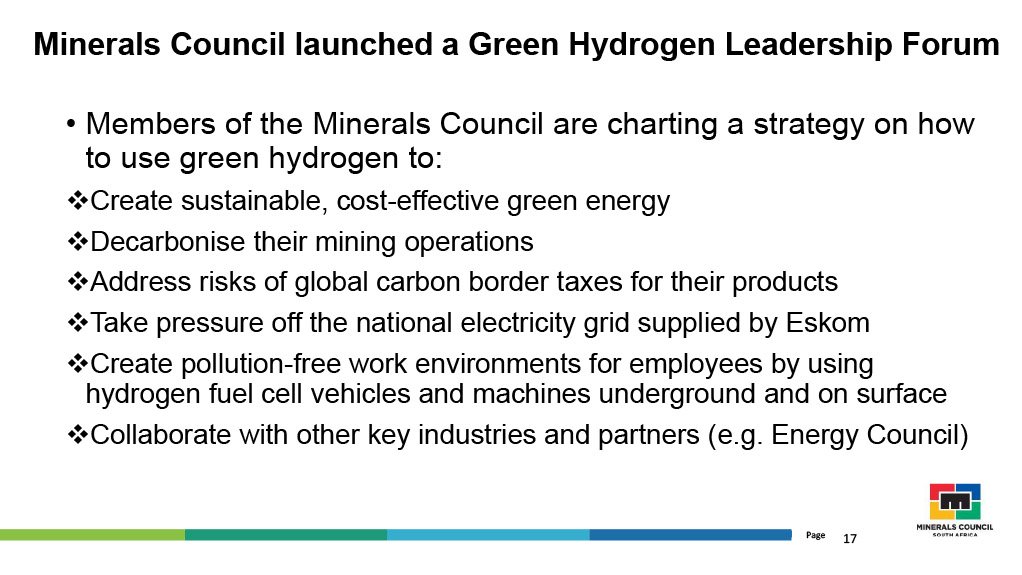

GREEN HYDROGEN LEADERSHIP FORUM

The Green Hydrogen Leadership Forum of the Minerals Council is charting a strategy on how to use green hydrogen to create sustainable, cost-effective green hydrogen. The strategy also embraces decarbonising the mining operations of members, addressing risks of global carbon border taxes for their products, taking pressure off the national electricity grid supplied by Eskom, creating pollution-free work environments for employees by using hydrogen fuel cell vehicles and machines underground and on surface, and collaborating with other key industries and partners such as the Energy Council.

The world’s largest hydrogen-powered mine-haul truck, developed by Anglo American Platinum, saves 900 000 litres of diesel per truck each year.

Sibanye-Stillwater has partnered with Heraeus Precious Metals to jointly research and develop novel PEM electrolysers using ruthenium and scarce iridium.

Impala Platinum has implemented the first hydrogen fuel cell forklift and hydrogen refuelling station at its Springs refinery, as well as investing R25-million in fuel cell development in South Africa in collaboration with the government and academic institutions.

“PGMs are nothing without people. But the people of South Africa can make PGMs a critical industry for the future in partnerships that are going to help to change the world. If we have a vision and a plan, we can take our platinum group metals mining industry to a new level. It’s been a critical contributor to our economy so far but by 2050, another R8-trillion in current money terms is practically possible if we get it right,” said Baxter.

EMAIL THIS ARTICLE SAVE THIS ARTICLE ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here