JOHANNESBURG (miningweekly.com) – The brand-new platinum-catalysed hydrogen fuel cell system that has just been released for passenger cars reveals that fuel cells can be as cheap to manufacture as internal combustion engines (ICEs), UK company Intelligent Energy has highlighted in a release to Mining Weekly.

The company’s patented system has been designed to give passenger car manufacturers direct access to the smaller, more powerful, turnkey and commercially viable hydrogen fuel cell solution that is needed to make zero carbon emission mobility a reality in the passenger car market across the entire planet.

The hydrogen fuel cell developer and manufacturer has also confirmed that its innovative IE-DRIVE™ is a proton exchange membrane (PEM) fuel cell. PEM and platinum go hand-in-glove.

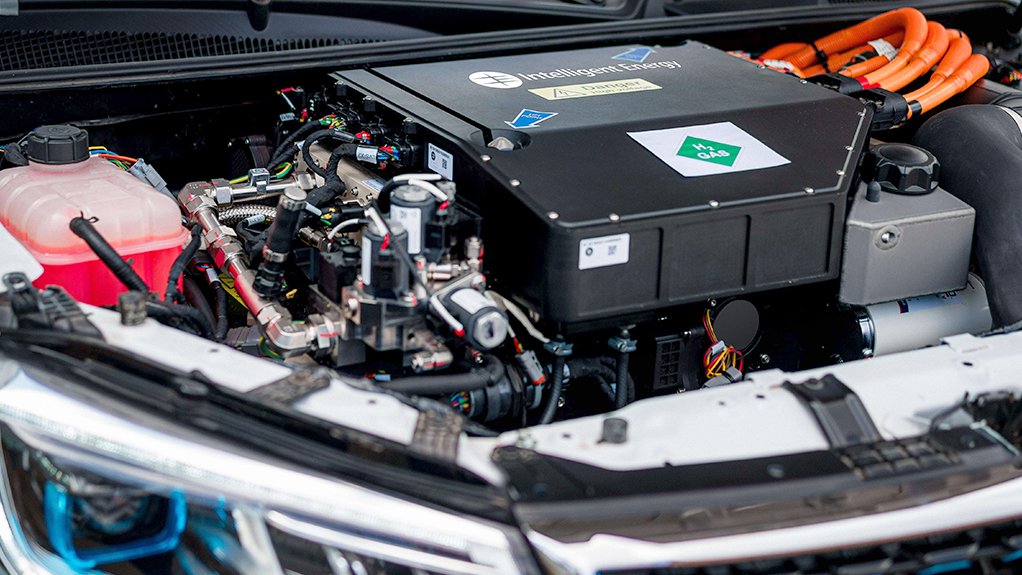

The single stack platform burst into the open during a launch event at Intelligent Energy’s Loughborough headquarters, where it powered a sports utility vehicle (SUV) provided by Changan UK.

The specification of the trade-marked platform is said by Intelligent Energy to bring “significant benefits” when compared with other fuel cells that have been developed by large automotive groups and their third party fuel cell suppliers.

MORE POWER, SMALLER, SIMPLER

In its current configuration, the fuel cell stack is capable of 157 kW gross electrical power, which is said to be higher than any other single stack application that is currently available for the passenger car sector.

The patented direct water injection technology means that the system’s heat exchanger is up to 30% smaller than its competitors at equal net power output. The single pass heat exchanger in the system’s test SUV measures only 0.34 m² but enables cruising at 130 km/h in peak temperatures and a speed of 90 km/h to be achieved when travelling up a long, steep hill. Having a small heat exchanger makes vehicle packaging much easier and benefits fuel cell vehicle design, particularly in relation to bonnet height and improved driver visibility, Intelligent Energy stated.

Designing its novel direct water injection system has allowed Intelligent Energy to reduce its component count and bill of materials. An example of this is shown by the fact the system’s fuel cell does not require a humidifier and related parts.

TURNKEY, COMMERCIALLY VIABLE

The fuel cell system, which has a traditional engine shape, meets the low bonnet requirements of passenger cars while including the fuel cell stack, electronic control unit, heat exchanger and balance of plant.

“It represents a genuine turnkey solution for car manufacturers,” Intelligent Energy stated.

Under full-scale, volume manufacturing conditions, the company predicts that its fuel cell system will cost around £100 per kW by the end of the decade, making it less expensive than battery electric vehicle solutions and comparable with ICEs.

The quest to develop a new breed of patented hydrogen fuel cell technology is the result of a four-year project that got underway in November 2019, supported by the Advanced Propulsion Centre.

The £22-million initiative was a collaborative effort involving Intelligent Energy, Changan Research & Development Centre, Lyra Electronics and Alexander Dennis. Changan provided essential support during the project, including the provision of three SUVs to enable fuel cell testing.

Throughout the entire project, Intelligent Energy has revolutionised its manufacturing processes, streamlined assembly, and worked to secure new cost efficiencies without sacrificing quality.

Intelligent Energy is now ready to roll its technology out to the passenger car market, in partnership with suitable car manufacturers.

“With 25% of all passenger cars expected to have hydrogen fuel cell powertrains, this clean technology represents the future,” said Intelligent Energy CE David Woolhouse.

“Our product has the potential to shake up the hydrogen fuel cell market and accelerate the transition towards zero-emission mobility,” Woolhouse added.

As an International Automotive Task Force-compliant business, the company is looking to grow its capability as a tier 1 supplier and sees fuel cell manufacturing as a major driver of economic growth.

The support provided by the Advanced Propulsion Centre has been acknowledged, with Intelligent Energy programme director Dr Ashley Kells describing it as being fundamental to the development of the passenger car fuel cell system, along with the valuable input of the other programme partners.

“The IE-DRIVE™ product is a ground-breaking advancement in the automotive industry and the work we have undertaken clearly illustrates the UK’s ability to be a global leader in the hydrogen fuel cell arena,” said Kells.

The addressable global fuel cell market for passenger cars and vans is anticipated to be worth $750-billion (£596-billion) by 2040, and if car manufacturers adopt its IE-DRIVE™ fuel cell technology, the company could scale up its manufacturing capability in the East Midlands – a move that would create significant new employment opportunities and provide a major boost to both the regional and UK economy.

“Once again, Loughborough is in pole position with Intelligent Energy at the forefront of hydrogen vehicle technology,” said Loughborough MP Jane Hunt.

The Advanced Propulsion Centre is seen as performing outstandingly in supporting the automotive sector in the net zero transition.

Privately owned Intelligent Energy has 600 patents in place, with its activities also spanning markets in the US, China, South Korea and Japan.

EMAIL THIS ARTICLE SAVE THIS ARTICLE ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here