JOHANNESBURG (miningweekly.com) – The world’s producer of the purest manganese metal is becoming greener and cleaner as it repositions for market acceptance in the battery electric vehicle (BEV) market, where it sees phenomenal growth potential.

Manganese Metal Company (MMC) of Mbombela (Nelspruit) is already finding greener sources for the one-gigawatt hours of energy that it needs a day.

Remarkably, in the last 18 months, it has been wheeling hydropower from Lydenburg, also in Mpumalanga.

Some 1.8 MW of green power from a hydropower station in the Crocodile river is being commissioned, following the completion of a process of selection of a vendor for the supply of solar photovoltaic energy. (Also watch attached Creamer Media video.)

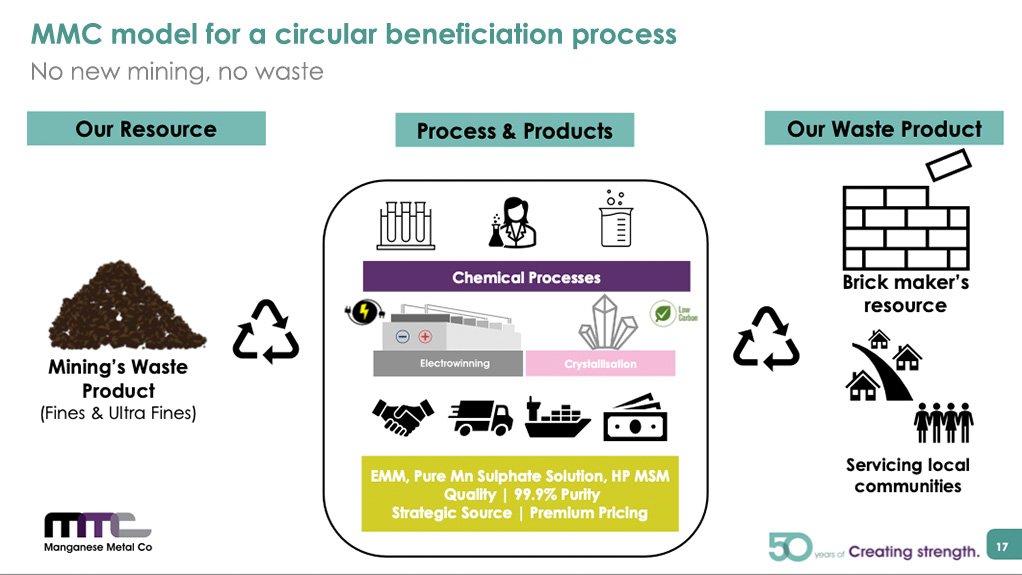

As part of a circular beneficiation model being introduced, a more sustainable alternative of using landfill material to make clay bricks for local communities is being put in place.

As the single largest user of potable water in Nelspruit, projects to recycle and clean water are on the go to elevate MMC to globally acceptable levels as an exporter. Currently, 56% of the electrolytic manganese metal (EMM) it produces is sold to Japan, 25% to the US, and 10% to Europe. The EMM is 99.9% pure, beating the next highest 99.7%

For the last 49 years, MMC has taken the waste product of manganese mining in South Africa, the fines, and beneficiated them using chemical processing and large quantities of electricity to make 3% of the world’s manganese metal.

“We are the only non-Chinese producer, but fortunately we make the best manganese metal, the purest manganese metal in the world, and therefore we feed into a quality niche market in which nobody else can really compete,” MMC chairperson and mining stalwart Bernard Swanepoel told Mining Weekly during Friday’s MMC Open Day.

In days gone by, MMC was operated by a Samancor structure on behalf of BHP Billiton and Anglo American. Today it is owned by MM Holdings, which is in turn held 70% by Bright Resources and 30% by To The Point.

A far-reaching new horizon is now extending for MMC, well beyond the EMM market into the burgeoning BEV market, with manganese sulphate.

For some time, customers have been buying the company’s manganese metal to dissolve it and make manganese sulphate, which has prompted the manganese sulphate extension by MMC itself.

“Once the 5 000 t/y plant is built, accredited and goes into all the batteries of the world, then the sky’s the limit. Then MMC can truly step out and put South Africa on the map again,” said Swanepoel.

Manganese is going into BEVs and battery energy storage for good technical and cost reasons. Formulations are increasingly including manganese in batteries, which is drawing MMC more deeply into the battery minerals market.

“China already owns this space. That’s true for strategic minerals, for battery minerals. Ninety per cent of the world’s refining capacity is in China. We are an example of one little facility outside of China in the manganese space.

“There’s a huge opportunity for us to grow into that space but we’ll have to be world-class, safe, environmentally friendly and be price competitive. This is a game full of politics and we sit here on the southern tip of Africa on the eastern side of the country, with logistics and other challenges.”

But despite these challenges, MMC has decided to focus on the phenomenal opportunity, starting as it does with special South African skills ready to be leveraged.

In its last financial year, MMC, which has 400 direct employees and 200 indirect contractor employees, earned South Africa R2.28-billion in export revenue, exporting mainly through the ports of Maputo and Durban, and paid R179-million in taxes.

EMAIL THIS ARTICLE SAVE THIS ARTICLE ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here