JOHANNESBURG (miningweekly.com) – The use of manganese in batteries for battery electric vehicles is being increasingly explored, with density, charge, costs and durability being among the factors that are putting the hard grey metal with which South Africa is well-endowed on a pedestal.

The latest highlight of this is the selection of a North American manganese project being developed by Johannesburg-, Sydney- and London-listed South32 for a financial grant to support the potential development of a commercial-scale manganese production facility.

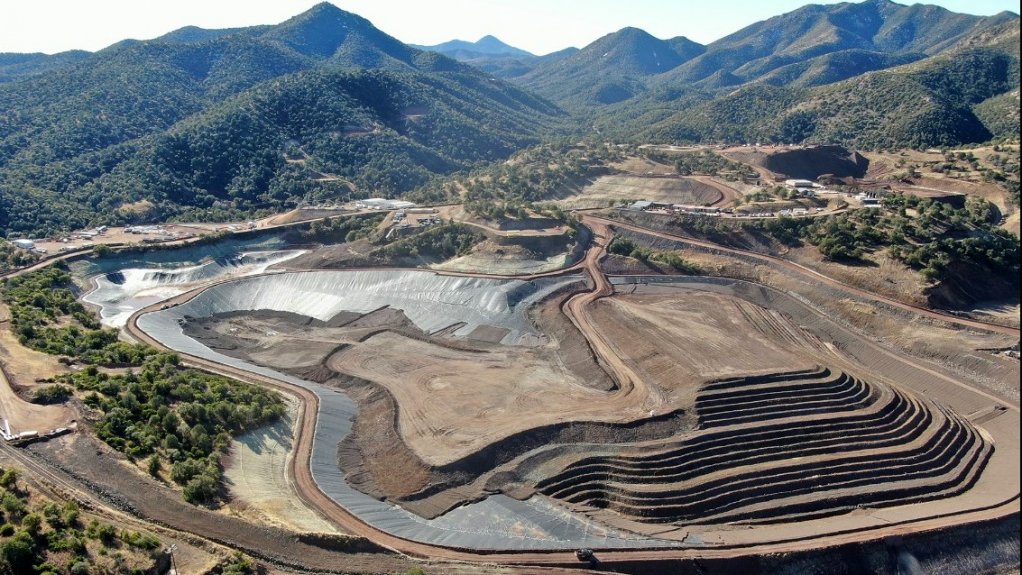

Involved is the United States Department of Energy’s (DoE's) selection of the Hermosa project in Arizona for a $166-million award negotiation from its Battery Materials Processing and Battery Manufacturing Programme.

The grant will support the hoped-for development of a commercial-scale facility to produce manganese, which South32 already does at considerable scale in South Africa’s Kalahari Manganese Field, which is by far the largest land-based manganese deposit on earth and the world's top producer of manganese metal tonnage. South32’s other manganese-producing operation is Gemco in Australia, which was recently impacted by a cyclone.

“We welcome this grant,” said South32 CEO Graham Kerr, who described it as recognition of the promise of Hermosa’s Clark deposit to likely supply battery-grade manganese to the emerging North American market.

“Hermosa represents a regional scale project with the potential to produce commodities critical to a low-carbon future across multiple deposits for decades to come,” Kerr added in a release to Mining Weekly.

“Following the final investment approval earlier in the year, construction of our large-scale, long-life Taylor zinc/lead/silver project is progressing as planned.

“Our investment in Taylor will unlock value for future growth options, including Clark, by establishing significant shared infrastructure.

“In addition to Taylor and Clark, we are continuing further exploration programmes at Peake to test the potential for a continuous copper system connecting Peake and Taylor.”

On a cost-share basis, the DoE will, subject to final negotiation, provide 30% of the cost of the manganese production facility, up to $166-million.

Construction of the facility and the development of Clark represents an opportunity to establish a North American supply chain of battery-grade manganese in a phased approach in line with market development.

Potential customers are being engaged to advance product qualifications for battery manufacturing, including potential agreements for future supply following the signing of multiple non-binding memoranda of understanding.

A decline at Clark to enable bulk sampling through a demonstration plant and further underground exploration is under construction and decline access is scheduled for the end of 2025. This work is being supported through a $20-milion grant through the Defence Production Act Investment Programme.

MANGANESE METAL COMPANY

Interestingly, South African Manganese Metal Co (MMC) of Mbombela, Mpumalanga, is making a first-mover advance to enter the manganese battery metal market, which is progressing super-fast.

Being established by MMC is a faster stream to market, ahead of the company becoming a manganese-ore-to-sulphate producer from its current position as the world’s purest 99.9% pure manganese metal from manganese fines.

“From Mbombela, this is a phenomenal exponential expansion – the South African story taking a big step forward,” MMC chairperson Bernard Swanepoel explained to Engineering News & Mining Weekly in a Zoom interview in which MMC CEO Louis Nel provided detailed insight on May 31.

“However, just as China did not wait for the world and America and Europe are not waiting for South Africa, the battery space is developing super-fast. We do not have to back a technology or a combination of minerals. We will be supplying manganese in the shape and form that the precursor manufacturers want it to these manufacturers as soon as possible.

“For us to do that, we have to dissolve some of our current metal, which is already 99.9% pure, and then, in order to ship it to where it’s needed, we recrystallise it and we ship manganese sulphate,” Swanepoel explained.

With the crystalliser, MMC is leapfrogging over its own ore-to-sulphate project.

Manganese sulphate is the form in which precursor manufacturers want manganese because it is as sulphate that they blend it with lithium, nickel and cobalt.

But as much as there is an abundant supply of manganese ore as such, there is absolutely limited capacity to make pure manganese metal, which MMC has been doing for half a century. Outside of China, MMC is the only producer.

While continuing to provide its traditional offering to export markets, MMC will now also be using its pure manganese metal to produce manganese sulphate for batteries, ahead of launching a manganese ore-to-sulphate project.

JUPITER MINING

Australia-listed and South Africa-operating Jupiter Mines, which is also eyeing the manganese sulphate opportunity, has produced a 99.9%-pure sample using the Northern Cape’s manganese ore and bringing into service an internally developed hydrometallurgical production process.

Jupiter CEO Brad Rogers foresees high growth in demand for battery-grade manganese.

Jupiter’s operating Kalahari mine, Tshipi é Ntle Manganese Mining, is 49.9%-owned by Jupiter and 50.1% by Ntsimbintle Mining.

Jupiter’s laboratory sample of high-purity manganese sulphate monohydrate (HPMSM) – produced using 28% to 32% manganese content Tshipi ore – was reportedly within required tolerance limits for all specified impurity levels. Ntsimbintle Mining, chaired by South Africa’s Saki Macozoma, owns 51.1% of Tshipi and Jupiter 49.9%.

Should further work prove successful, Jupiter intends to build and operate a HPMSM conversion facility, into which it will invest equity alongside co-investment from various external sources.

DEMONSTRATION PLANT

Meanwhile, the Botswana Ministry of Minerals and Energy has granted Canada's TSX-V-listed Giyani Metals Corp a mining licence for its K Hill battery-grade manganese project, for which it has secured $26-million in financing from South Africa’s State-owned Industrial Development Corporation and ARCH Sustainable Resources Fund and to progress the K Hill sulphate manganese project in Botswana to construction.

Giyani reported this month that its battery-grade manganese demonstration plant, which is under construction in South Africa, is scheduled to be commissioned during the fourth quarter of this year.

The product from the demonstration plant will be used for offtaker qualification.

EMAIL THIS ARTICLE SAVE THIS ARTICLE ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here