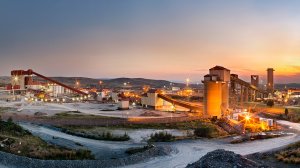

JOHANNESBURG (miningweekly.com) – The South African operations of Harmony Gold did very, very well in the six months to the end of December last year load curtailment notwithstanding, Harmony Gold CEO Peter Steenkamp said during a media call on Wednesday.

“There are many mines that performed above expectation,” Steenkamp said in response to Mining Weekly. (Also watch attached Creamer Media video.)

The high performance of Harmony’s Mponeng and Moab Khotsong underground gold mines was driven by an increase in tonnes milled and an improvement in underground recovered grades.

Operating free cash flow from these two mines increased by 7% to R1 043-million in the six months on grade and price.

At Mponeng, underground recovered grades increased by 20% to 8.72vg/t, resulting in a 13% increase in gold production.

At Moab Khotsong, the Zaaiplaats project is progressing and feasibility studies to determine the possibility of deepening Mponeng and conducting pillar extractions at Savuka and Tau-Tona are underway, for likely conclusion as part of the JSE-listed company’s annual planning cycle in August.

Harmony’s net profit soared 36% to R1.9-billion on a 6% increase in revenue to R23.3-billion.

“The management programme that’s been a part of Harmony for many years worked exceptionally well during the half-year. With the good safety you get a very good feeling at the mines when you are there. The culture’s good, people are positive and want to perform, and for me that was the big takeaway, and we can continue with the momentum going forward,” he added.

While loadshedding is a massive issue, Harmony is succeeding in managing it. “I don’t want to underplay the problem, but if you look at our results, I can’t say that they have been impacted by loadshedding, which is due to the good work that Beyers Nel and his team have done in managing its effect,” said Steenkamp. Nel is Harmony’s group COO.

“We have load curtailment, not loadshedding, so we can decide on where we are going to cut loads of certain areas and at many of our mines, we do have the luxury of maybe hoisting when we don’t have load curtailment. I take my hat off to our engineering and operational teams for being able to do that,” he said.

All-in sustaining costs for the South African underground optimised operations increased by 8% to R914 454/kg ($1 642/oz) mainly owing to the ongoing project at Target 1 and lower-than-planned underground recovered grades

at Kusasalethu.

Operating free cash flow margins from Tshepong North improved to 8% from -10% and Tshepong South improved to 18% from 8%. Joel’s operating free cash flow margin improved to 12% from -16%.

MPONENG DEEPENING

Harmony is expected to complete its feasibility study into the deepening of Mponeng by the end of this financial year at the end of June. “We have to press the button on this by the end of the calendar year at the latest, but hopefully it will be earlier than that,” said Steenkamp.

There is an option of building smaller declines in the high-grade areas or continuing with the current declines. It depends on what provides the most flexibility.

The feasibility done by previous owner AngloGold Ashanti is being redone to see what additional opportunities can be created.

“It’s a very exciting project on an excellent orebody and in a good jurisdiction and all the options are being studied,” Steenkamp added.

PAPUA NEW GUINEA DROUGHT

The prolonged drought in Papua New Guinea has impacted Papua New Guinea Power Limited's hydroelectric power generation and supply.

On-site diesel power generation has been necessary at a higher cost. The commissioning of the Baime run-of-river hydroelectric facility in Bulolo, 40 km from site, is due to be completed by mid-year. Once completed, this will improve the power generation challenges and reduce the on-site diesel power generation requirements.

Half-year gold production at Hidden Valley in Papua New Guinea increased by 6% to 1 983 kg (63 755 oz). Recovered grade improved by 2% to 1.00 g/t from 0.98 g/t in the comparable reporting period.

Further upside in recovered grade is expected as the high-grade areas at Kaveroi and Big Red are accessed.

Production trends in crushed material transported by the overland conveyor belt continue to improve since the implementation of a dedicated improvement programme after the conveyor belt failure.

All-in sustaining costs increased by 10% to R1 204 686/kg (US$2 162/oz) owing to the increase in diesel costs.

SURFACE OPERATIONS DOWN

Half-year production from surface sources fell 12% to 3 875 kg (124 584 oz) owing to the depletion of the rock dumps and lower recovered grades at Mine Waste Solutions. Surface production was also negatively impacted by the cyanide shortage, which has now been resolved.

EMAIL THIS ARTICLE SAVE THIS ARTICLE ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here