JOHANNESBURG (miningweekly.com) – The extraction of data from machinery to improve decision-making is a key benefit of the digital mine and has changed the way that mines manage their assets and perform machine maintenance, Australia Mining managing editor Ben Creagh said on Wednesday.

Creagh was speaking during a virtual presentation at which ifm Australia’s Freddie Coertze described the Covid-19 pandemic as a catalyst for the prioritisation of digitisation and Aditya Kunder outlined how software was updatable over the air and how modern car and cellphone technology was being industrialised in robust form for migration to mining.

While the adoption of digital technologies had been largely incentivised by cost savings and productivity gains, Creagh said during the presentation covered by Mining Weekly that coronavirus had focused attention on the value of operating remotely and autonomously.

Condition monitoring had become more affordable through the availability of remote wireless sensors and Cloud connectivity, and the scalability of condition-based and remote monitoring had rendered this a viable option for all types of mines, regardless of their size.

Importantly, cost savings and productivity gains had incentivised the adoption of these technologies and Covid had been highlighting their value by reducing recent impacts.

“It’s no longer a question of whether miners can afford to adopt the technologies that put them on the trajectory to predictive maintenance and interoperability. The reality is that miners cannot afford not to,” Creagh contended during the webinar, which pointed out where starts should be made and how technology already in place can be enabled prior to integration across the entire operation.

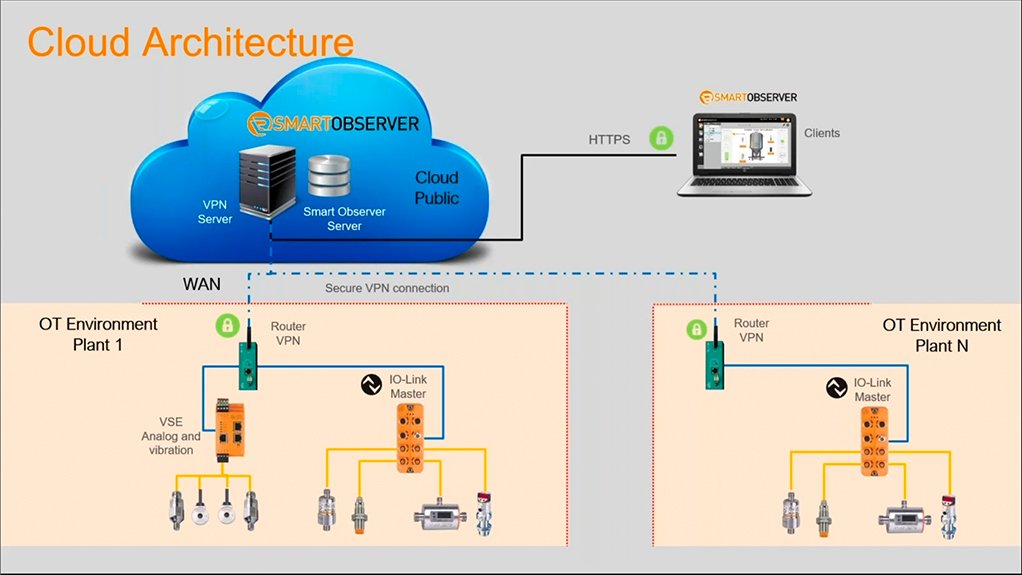

Coertze, who is also the company’s Industrial Internet of Things (IIoT) specialist for digital strategy, said the rise of the IIoT was making it easier for organisations to use intelligent maintenance software in data collection, integration with connected devices and smarter maintenance.

IIoT had, he said, become a reality in the day-to-day working environment of many companies and the mining world was now on verge of entering the next revolution, namely Industry 4.0, which is the automation of traditional manufacturing and industrial practices, using modern smart technology.

“This is going to change the control systems architecture, systems connectivity and sensors as we know it,” Coertze forecast.

“Tasks that have been thought of as undoable have now become even more affordable than ever before. Industry 4.0 was once a dream; now this is becoming a true reality,” he added, cautioning, however, that digitisation did not just happen with the flick of a switch.

He described predictive maintenance as a corporate philosophy and outlined how large volumes of data from devices needed to be analysed on maintenance-centric IoT platforms, which would be a major part of Industry 4.0.

“Scada and control systems are used mainly by the plant operators. Why not create a similar platform to inform your maintenance team way in advance,” he asked.

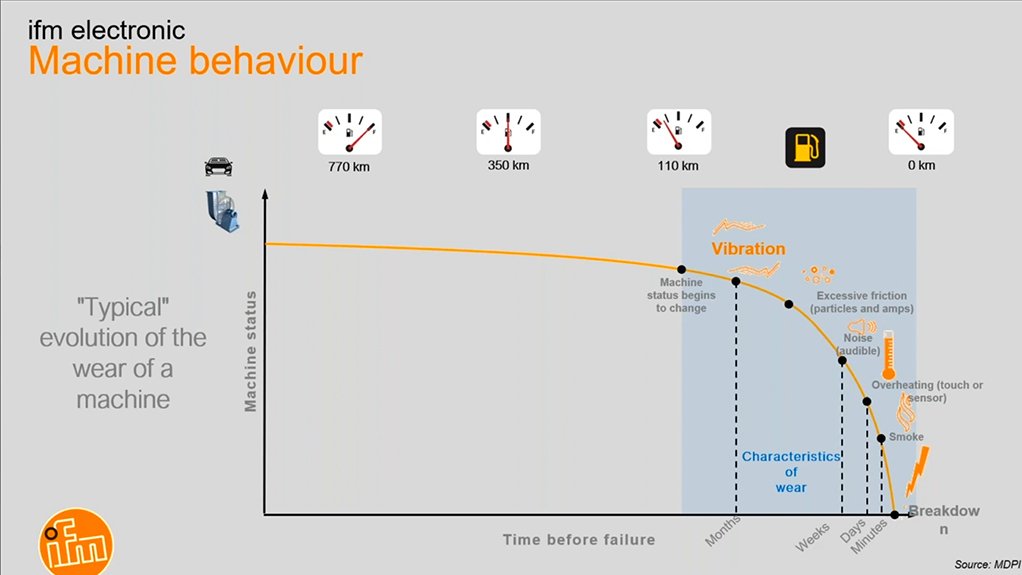

The other major aspect of Industry 4.0 was how businesses utilised the data collected and analysed from their systems, which would provide information on important aspects of the machine’s condition, such as premature machine failure.

“In order to do predictive analytics, it’s important for the sensors and the field devices to create meaningful data. This data generated has to address the failure modes or process information pertaining to the machine, for example pressure temperature and vibration,” said Coertze.

This data generated from sensors had to be easily available and be based on generic protocols like HTTPS, which stands for hypertext transfer protocol secure, and MQTT, meaning message queuing telemetry transport, and must not be vendor specific. Once the data reached the IIoT platform, analytic systems acted on it and provide detailed information back to the key stakeholders of the organisation.

Kunder, ifm Australia product sales manager for mobile control systems, spoke on the foundation of digitalisation and software updates over the air based on advanced analytic models and the migration and industrialisation of modern technology in cars and cellphones to the mining industry in robust form.

He said the technology had advanced significantly owing to Covid and more and more could now be done remotely. Robustness, storage, software updates, predictive maintenance, optimised touch, monitoring, intuitive voice alarms and advanced analytics could all be provided over the air.

Exemplified was a mining vehicle with sensors providing data to the system, collecting information that it was programmed to collect and forwarding the smart data to the Cloud for further analysis.

Benefits included remote and local monitoring, analysis of fuel behaviour to optimise fuel efficiency, downtime minimisation and the identification of which spare parts would be needed in the short term and which would be needed later thereby avoiding the cost of carrying excess stock.

EMAIL THIS ARTICLE SAVE THIS ARTICLE ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here