JOHANNESBURG (miningweekly.com) – Diversified mining company Anglo American is taking steps to position itself as a favoured iron-ore supplier to green steel producers.

The London- and Johannesburg-listed company is doing so amid half of its Scope 3 emissions relating to its iron-ore business and, in total, about 77% of its Scope 3 emissions arising from the steelmaking value chain. (Also watch attached Creamer Media video.)

Scope 3 emissions impact indirectly on a value chain, and are beyond the boundaries of a company’s own Scope 1 and Scope 2 emissions.

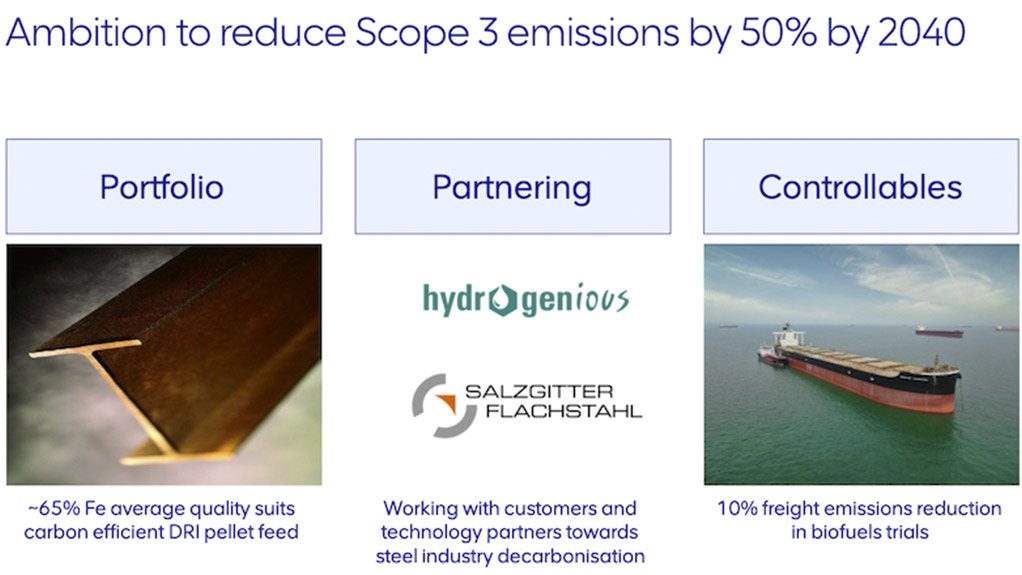

The decarbonisation of steelmaking is, thus, key to Anglo’s reducing its Scope 3 emissions, which it is intent on halving through partnership and collaboration by 2040.

“We’ll continue to work with the steel industry towards achieving the 1.5°C pathway, which will reduce our Scope 3 emissions by around 80% by 2040, against the 2020 baseline,” Anglo CE Mark Cutifani said on Thursday during the company’s Sustainability Performance 2022 April Session covered by Mining Weekly.

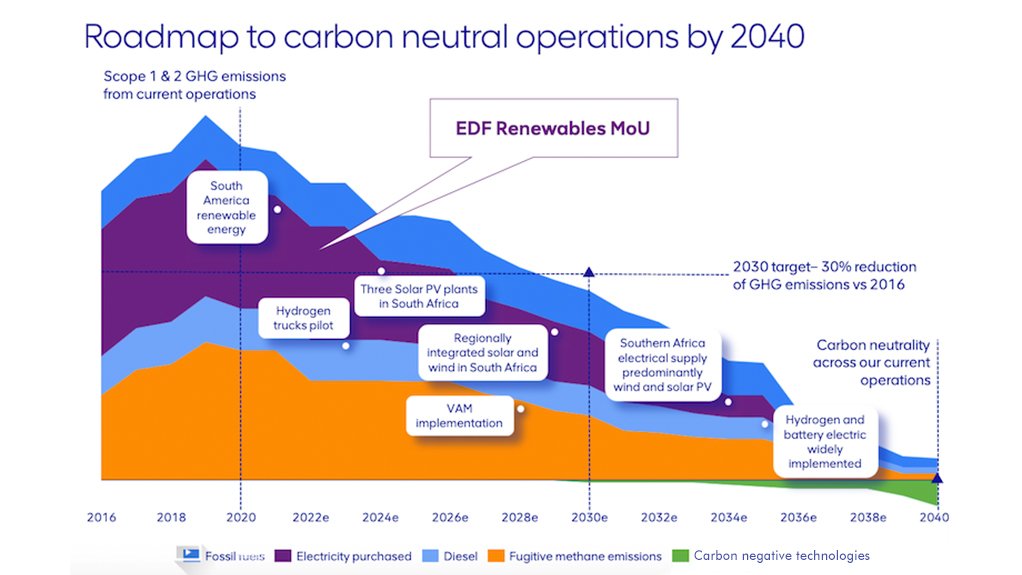

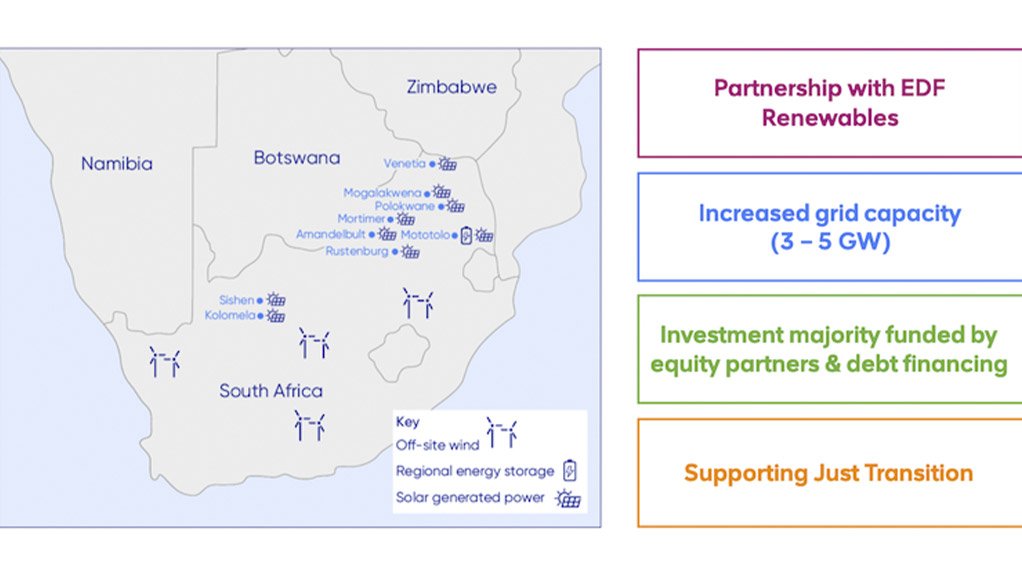

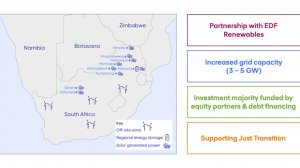

Cutifani said that Anglo's ecosystem approach to deliver renewable energy to mines instead of a mine-by-mine approach would provide opportunities to connect the Scope 3 value chain participants and, therefore, directly impact on their emission profiles. (Also see attached graphic.)

The high-quality iron-ore in the Anglo portfolio suits clean and modern steelmaking. The quality helps to enable a 20% to 25% reduction in carbon emissions in the steelmaking process, compared with a 58% reduction achieved from an iron-ore blend, for example, from other areas.

Anglo is working to improve iron-ore product qualities still further as it levers what it can directly control.

“Certainly, [there is] a very strong case for our niche position in iron-ore and certainly one that supports our high-margin delivery from the business as well. We also continue to work with our customers to advance technologies in these areas and others,” said Cutifani.

For example, Anglo’s 65% iron (Fe) iron-ore quality is being viewed against German company Salzgitter Flachstahl’s embarking on a big transformation programme to move away from steelmaking based on blast furnaces, towards steelmaking based on carbon efficient direct reduced iron, or DRI, pellet feed.

As part of this, Anglo is working with Salzgitter Flachstahl to study if its lump ore can be used in its process, and if so, how much.

In response to Barclays analyst Ian Rossouw's questions regarding Anglo’s 2040 Scope 3 targets and the consequences of its iron-ore and metallurgical coal mine lives extending beyond 2040, Cutifani said what Anglo was trying to do with iron-ore, in particular, was is to position itself as a favoured supplier to green steel producers through the quality of the products it produces.

In his swansong sustainability presentation before passing on the baton to CE-designate Duncan Wanblad, Cutifani outlined the quality of the group’s iron-ore operations of Kumba Iron Ore in South Africa – where he referred to work being done by Bulk Commodities CEO Themba Mkhwanazi and current Kumba Iron Ore CEO Mpumi Zikalala – as well as to the quality of the iron-ore at Minas Rio, Anglo’s iron-ore operation in Brazil.

“At Minas Rio, we are at 67% Fe and attempts are being made to reduce silica and use technology to reduce other deleterious elements in the ore,” said Cutifani.

The difference between the 67% Fe Minas Rio product and a Pilbara 58% Fe product from Australia was, he said, about 25% to 30% in terms of Scope 3 emission reduction.

In the case of Kumba, whose product is about 64.5% Fe, with a bit more silica and other issues, the Scope 3 improvement potential was only 20%. Effort was being made to make Kumba’s product more attractive to go into the green steel mix so that Anglo becomes part of the solution to 2040.

“What we want is to have the best iron-ore product so that it is improving and enhancing values for us and margins. If you look at the margins of Kumba and Minas Rio today, their improvement, compared to lower-grade alternatives, is significant, and that’s also driven a big improvement in our returns to shareholders, so it’s a virtuous circle and were going to keep on that track.

“. . . we think that being part of the green steel revolution is actually the key to going beyond 2040 in both of those. Obviously, we’ll need exploration success at Kumba, and at Minas we have gone well beyond that life-of-mine. We think we’re in the right strategies for iron-ore," he said.

In terms of metallurgical (met) coal, Cutifani said Mkhwanazi had already put the challenge to the team in terms of what can be done to improve performance and how work with partners could reduce the Scope 3 emissions impact of met coal.

What was now being considered was whether carbon capture or other technologies would need to be in place by 2040, in order for Anglo to continue to be a preferred supplier of high-quality hard coking coal.

“We don’t have those solutions . . . so it’s not in our base plan and, at the moment, you see us depleting our met coal resources before 2040. For us to be successful beyond 2040 with met coal, we’re going to have to have the solution because, ultimately, if you add the carbon cost that you would have to carry, you have to have a solution. We don’t have that yet, were not going to give that up, that's what the guys are working towards.

“Obviously, we’re an important player today in lower carbon emissions from steel because we have high-quality hard coking coal, which . . . provides about 20% or 30% of lower carbon emissions as part of the overall process,” he said.

But Anglo would have to have a different solution by 2040, and that was what Mkhwanazi and the team were working on.

“If that can’t be found, it’s very difficult for us to imagine being in met coal beyond 2040, but we won’t give that away and certainly Themba’s not going to give that away,” Cutifani said.

LOWER CARBON CHARTERED SHIPPING FLEET

In a further bid to reduce Scope 3 emissions, Anglo has ordered ten liquified natural gas vessels for its chartered fleet, which are said to offer environmental benefits that include a 35% reduction in carbon dioxide emissions, compared with the reduction when using standard marine fuel, while addressing the old problem of methane-slip-through technology.

This follows the company’s recently announcing the successful sea trial of a Capesize vessel powered by a biofuels blend from French multinational Total Energies, which resulted in a 10% emissions reduction – an improvement on its previous trial in June last year that achieved a 5% reduction.

This is part of a pathway to achieving carbon neutrality by 2040.

EMAIL THIS ARTICLE SAVE THIS ARTICLE ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here